| Building with Pumice by Klaus Grasser / Gernot Minke published by Deutsches Zentrum, 1990 |

In many Third World countries, bonding agents like cement and lime are disproportionately expensive. In the late 1970s a mason in the Federal Republic of Germany had to work about 20 minutes to earn enough to pay for a bag of cement. At the same time, a mason in Guatemala, India or Bangladesh had to work three days to earm the "same" bag of cement. In terms of wages, cement was roughly seventy times as expensive there as it was in the Federal Republic of Germany.

That fact prompted the Research Laboratory for Experimental Building at Kassel Polytechnic College to investigate the question of how natural building materials like sand and gravel could be used for building houses without the necessity of using such binders. The use of fabric-packed bulk material was found to be the most cost-efficient approach. In that connection, various ways of producing and applying such materials had to be developed and tested. Pumice proved to be an exceptionally good bulk material for such applications, because it weighs less and has better thermal insulating properties than ordinary sand and gravel. The first trials were conducted in 1976, with a 2.20 m high column with a frustum-shaped shell made of PVC-coated polyester. Open at the top, the column is rendered stable by the bulk filler and its conical shape. The internal pressure generated by the filling stretches the jacket tight and keeps it from collapsing. The column's load-bearing capacity depends on the tensile strength of the jacket. The column is capable of accepting a load of more than 10 kN (1000 kg). A load-bearing arch can be made by filling an arch-shaped fabric tube with sand - the only trouble being that filling the tube is very time-consuming. In 1977 a dome-shaped experimental structure made of fabric-packed bulk material was erected on the research laboratory's test grounds. The structure is 3.20 m high, has an outside diameter of 4 m and consists of 220 m of thin polyester hoses. The hoses are filled with the aid of a vacuum cleaner-driven bag filler of in-house design. A pair of vacuum cleaners draw the bulk material into an elevated funnel (up to 3 m high). The bags are attached to the bottom end of the funnel. When the vaccum cleaners are turned off, a gate at the bottom of the funnel opens automatically, letting the bulk material fall into the hose. The empty hoses have a diameter of 20 cm; after filling, they take on a elliptical shape, i.e. about 11 cm high and 25 cm wide. The structure is erected by placing the hoses on top of each other in concentric rings of decreasing radius. The dome-shaped structure has a cross section that roughly corresponds to the shape of an inverted catenary. The desired shape is obtained with the aid of a rotating vertical template mounted at the center of the structure. The round opening at the top is reinforced with a supplementary steel-pipe compression ring and covered with a mushroom-shaped member that can be raised for venting. Filling the hoses takes about 7.5 man-days, and the erection work, including manufacture of the compression ring and cover, takes approximately 12 man-days. Based on experience gathered during that project' the research laboratory designed and tested an earthquake-proof stacked-bag type of construction in Kassel in early 1978. The basic element consisted of 2.5 m long bags made of 0:5 m wide strips of burlap and filled with pumice gravel. The hose-like bags were knotted at the ends, bent double and stacked to yield 1.2 m wide wall members. Thin bamboo poles were pounded through the bags and fastened to a continuous tie beam (made of -slender pine poles) at the top to make the stack stable. Several coats of whitewash were applied to keep the fabric from rotting and the wall from soaking up precipitation. Subsequent trials showed that it is a good idea to immerse the bags in lime slurry prior to use.

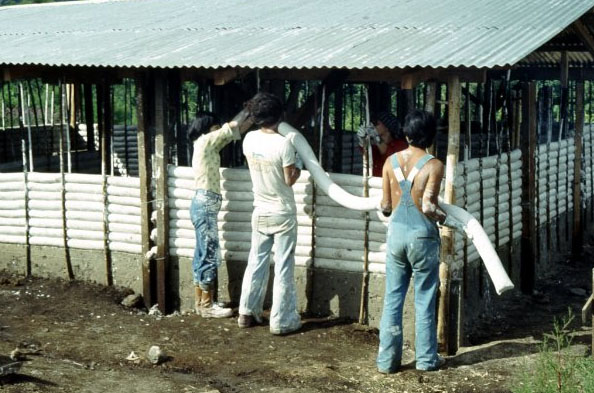

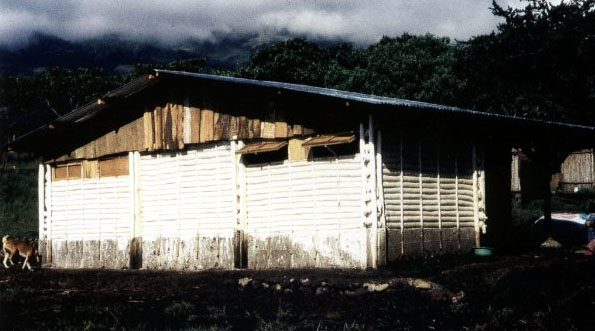

In connection with a joint research project conducted by the Research Laboratory for Experimental Buildings' the Francisco Marroquin University in Guatemala, and the Centro de Estudios Mesoamericano Sobre Tecnologia Apropiada (CEMAT), a 55 sq. m house made of stacked bags filled with pumice sand was erected in Guatemala in 1978 (above). This type of construction draws on prior experience with the aforementioned stacked-bag type of construction and was modifed as necessary to satisfy local requirements in Guatemala. The basic structural member for this system was a hose-like bag made of cotton fabric with a diameter of about 10 cm and a length of anywhere from 1.70 to 2.80 m. The bags were filled with pumice sand and gravel, then stacked and pressed together so that the originally round bags took on a rectangular cross section measuring roughly 8 x 10 cm with round edges. The bags were first dunked in whitewash and then stacked directly on a 0.1 m-wide and 0.8-1.0 m-high strip foundation/plinth made of natural stone masonry. Immersing the bags in whitewash prior to use ensures that the cotton fabric is saturated with lime as protection against rotting. Vertical bamboo poles placed at intervals of 0.45 m on both sides of the bags and interconnected with wire loops gave the stacked bags the necessary stability. The bamboo rods were fixed to the foundation and to the horizontal tie beam at the top. Additional stability was provided by thick, round or square timbers (6 -8 cm diameter) that were rammed 0.3-0.5 m into the ground at the end of each stack of bags (ca. 2.25 m). This wall-building system is flexible enough to accommodate the motion induced by an earthquake. The continuous tie beam at the top keeps individual wall members and the entire system from falling over. After the walls were finished, they were given two coats of whitewash inside and out to keep rain from soaking into the bags. Table salt and alum were added to the whitewash to improve the vapor diffusion capability of the finished coating and to protect it against the digestive attack of microorganisms (1 bag of lime to 4 kg table salt, 2 kg alum, and approx. 30 lifers water). With reference to seismic stability, the purlin roof structure was separated from the wall structure. It Tests on six roundwood columns, with interconnection provided by wooden struts. The building materials for the 55 m² house cost US $ 630.78, or US $ 11.46 per m². It took 6-8 workers about three weeks to build the house - meaning that labor only accounted for some 20 -25% of the total cost of construction.

Compared to a similar house built according to customary methods using cement-bonded cavity blocks, this house took about the same amount of time to build, but cut the cost of building materials by 48%. A different earthquake-proof mode of construction for fabric-packed bulk materials was developed by the research laboratory in 1977 and tested on an experimental structure in Kassel. This type of fabric-packed bulk-material wall comprises two rows of roundwood poles that are tilted toward each other and separated by two strips of fabric that are either sewn together at the bottom or nailed onto a lath and then filled with pumice gravel. The lateral pressure exerted by the bulk material is contained by driving the wooden poles into the ground and tying the top ends together. The 4 -8 cm-thick poles are 2.10 m long and spaced at 0.45 m intervals. The walls are 0.45 m thick at the bottom and 0.20 m at the top. As protection against ground moisture and splashing water, the walls were built on a cat 0.3 m-high plinth. The fact that the vertical poles are fastened to a flexible round-wood or bamboo-pole tie beam at the top and inclined toward each other on all sides ensures adequate stability to cope with vertical and horizontal seismic ground motion. Such wall members can be prefabricated. Rolled together, the poles and fabric making up a 10 m long section of wall turn into a single roll measuring 2.5 m in length and 0.5 m in diameter. This "shell" is easy to handle and haul, e.g. in a pickup, can be erected in a short time by two people, and then just has to be filled with loose pumice and sand. |

Reproduced below is the fifth and final chapter of this book which is titled "

Reproduced below is the fifth and final chapter of this book which is titled "