EarthbagBuilding.com

Sharing information and promoting earthbag building

| Home | History | Resources | Slide Show |

| About Us | Projects | Plans | Videos |

| Blog | FAQ's | Workshops | Testing |

| Search | Articles | Bulletin Board | Shelter |

| How to Fill Earthbags Questions answered by Kelly Hart |

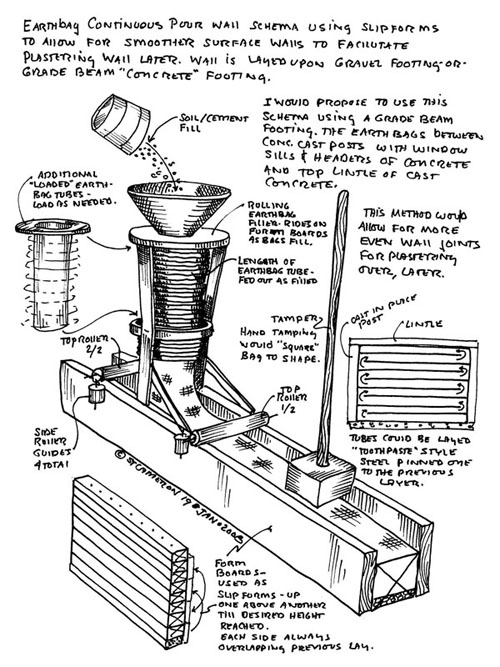

Q: I know that we are dealing with earth substances here, but how does one go about getting bags full of say, sand without having to hand-fill them? A: I suppose that you might find a company that sells bags full of sand, but this would be rare. The cost of transportation for such weighty materials would be quite high, compared to having the soil delivered locally. Also the bags are quite heavy, like sacks of cement, so there is lot of work involved in handling them as well. All of this is easier done at the building site. Q: Do we REALLY have to diddle the bags as shown in Doni and Kaki's book? It seems a smack with a hammer and thick earth plaster will cover them. Don't want to create any extra work. A: Diddling is one of those areas where Doni and Kaki reveal their fascination for perceived perfection. I have never diddled a bag, and simply give the point a bang with the hammer before plastering. If the bags you use happen to be pleated, even this is unnecessary. Q: Here is a sketch of a thought of mine about building with earthbags. Would you mind giving me your thoughts on this?

A: This is certainly an interesting idea, and a great drawing! I think that I understand your concept pretty well from the sketch. Here are my thoughts: The squared bag shape would only retain that shape if the contents were solidified, as would happen with a soil/cement mix (which you specify); looser material would eventually force the bags into their more natural oval shape after the form were removed. But then, I wonder, why bother with using the bag material at all? What you describe is pretty classic rammed earth with lifted forms, and there would be better adhesion with rammed earth directly upon rammed earth rather than with the bag material intervening. I might mention that rammed earth is often formed with slip forms done in lifts of maybe 2 feet. The proper soil mix is 15-30% clay and the rest sand. Sometime a small amount (maybe 5%) of Portland cement is added as a stabilizer, but not always. This is one area where earthbags have an advantage, because you can get away with a larger variety of soil mixes. Your suggested mix of 30% cement to 70% soil would be equivalent to a 3:7 mix of cement/sand concrete, which is very rich in cement! Standard soil cement mixes call for between 6 and 16% cement, depending on the specifics of the soil and the intended use. If the purpose for forming the earthbags this way is mainly to reduce the work and material in plastering, I have to say that I don't find the standard approach objectional. All those crevises between the bags give the plaster much better "tooth" than a smooth wall would, so there is an advantage to leaving these voids. I should add, though, that the apparatus and concept is very clever, and shows great inventiveness; I suspect that it would actually function quite well as drawn. C: This device was inspired by one I saw on a site featuring the Natural Building Colloquium in Texas 2007. I took the concept and redid it to my needs ended up with a new device. Here is a picture of it:

Q: I've been primarily interested in earthbagging for the low cost, but in my case any savings would be negated by the need to hire additional help. I do like the scoria approach, but I don't think we have much in the way of volcanic rock in my neck of the woods. I'm going to check into perlite to see if that's available hereabouts and if so, if it would be an affordable alternative. But if that doesn't work, I'll probably have to scrap the bagging idea and go with some other approach. A: (Owen) You could do most of it yourself and only hire an unskilled worker occasionally, mostly toward the end of the wall building. A bag stand in this situation would come in handy -- it supports the bag in place while you gradually fill it. For instance, you could hoist bags half full onto the slider and bag stand, fill the remainder, tuck the end under and position in place all by yourself. It's not the most efficient way, but you could go up to about 8' high doing this by yourself. And if you go with a lightweight fill material like scoria or perlite you can definitely do the whole house yourself. (Kelly did most of the work on his house.) Q: How far in advance can earthbags be made? I would have a place to store them away from sunlight, but I'd like to start building with a large portion of the bags already made. If this isn't the best approach, do you know how far in advance I could make adobe bricks? I would have room to dry them and store them away from water. A: There is usually not much point in filling earthbags in advance, since it is usually much easier to fill them in place, or at least near where they will be used to avoid heavy lifting. Also, if you are using a damp soil and tamping it for the greatest solid compaction, then this must also be done in place while the soil is still moist. Adobe blocks, on the other hand, do have to be made in advance and dried sufficiently to be able to handle them. So you can make and store as many of these as needed well in advance. Q: We will be throwing a barn raising event over a couple of weekends and think that a bagging machine would really help. A: One concern is that most sandbags for levees and such are smaller than is ideal for earthbag construction, so the machine may not be able to handle the larger bags. Another concern is that the best adobe-like fill material is damp and bit sticky, so it may not flow real well in the machines. With a group of coordinated people doing a bucket brigade and filling the bags in place, the filling and placing can go pretty quickly...I'm not sure that a machine would necessarily speed things up. Q: I was just wondering is it possible to build with earthbags in the winter months? Would there be problems with the temps causing the bags not to cure right? I am in North West Arkansas. If the cold temps would be a problem is there anything that could be done to help with it? What is the lowest the temps could get in your opinion without significant problems with the curing process? A: There are two possible problems with working in the cold season. One is if you are stabilizing the fill mix with cement, then this might not cure if it freezes. The other is that if your mix is damp and freezes it will expand some. This may actually not be that much of a problem depending on how far along your project is, since the bags will eventually settle and cure. I would say that if it is only occasionally dipping below freezing, then you are probably alright to continue, but if it is mostly below freezing, I would hold up until things warm up. Q: Is it important that the fill material is 100% free of organic matter? Anywhere on the land we take earth from, there are at least plant roots in it, even at deep levels. If we can't avoid having some plant matter in the fill material, do you think that adding some lime would have a counteract and stop the fill from decomposing? A: It is certainly best to avoid organic material in the fill, but a few small roots shouldn't be a problem. With too much organic material there is the risk of increasing compaction as it decomposes, and this can affect load bearing and such. Adding lime might delay any decomposition, but is not likely to arrest it entirely. Q: Are there details of the funnel available? The pictures are great, but not really enough to hand to our fabricators. A: There is nothing fancy about fabricating a funnel. You can use a section of large diameter PVC or metal pipe, a bucket with the bottom cut out, or I have used the top of an automatic chicken feeder... whatever fits the size of bag or tube you are u9sing. |

See Your Ad |

Disclaimer of Liability and Warranty

We specifically disclaim any warranty, either expressed or implied, concerning the information on these pages. No one associated with this site will have liability for loss, damage, or injury, resulting from the use of any information found on this or any other page at this site.

For Email contact go to About Us

We are interested in communication from others who are exploring the possibilities inherent with earthbag building.

Visit Our Other Websites:

www.greenhomebuilding.com

www.dreamgreenhomes.com

www.naturalbuildingblog.com